The Separation Packages with lammellar plates, also called Coalescents Plans (CPI), are commonly used to remove oil, grease and hydrocarbons having less water density

The wastewater is made to pass through the plate packs which, depending on the applications, can be constructed in different types of materials, usually polypropylene or FRVP

The particles of oil and fat contained in the wastewater adhere to the surface of the reed valve and, thanks to their low density, they move towards the 'high part.

An oil manual - or controlled skimmer collects the oil and fats from of 'water surface and conveys them in a storage volume from which subsequently is re-launched or removed for subsequent treatments

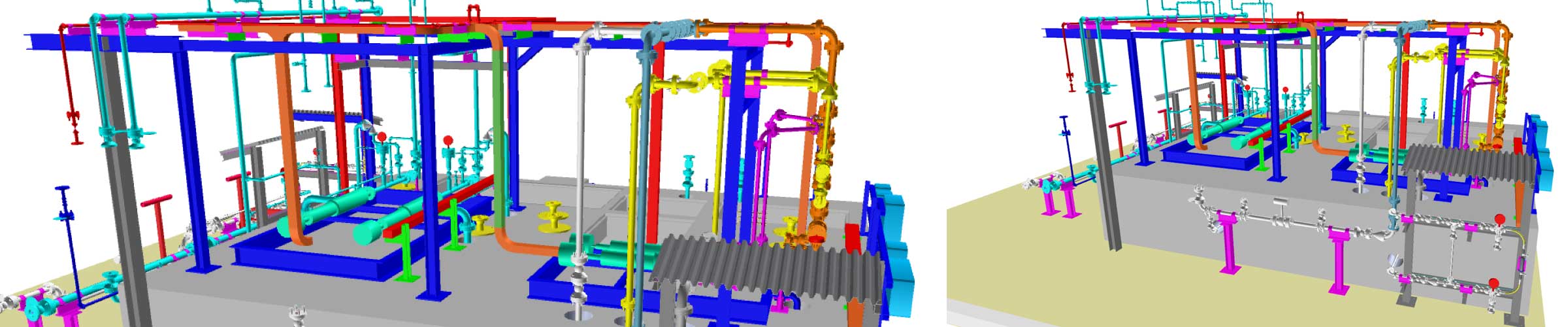

A typical package CPI-API separator can includes:

- The pumping skid with any sealing systems for special applications

- Internals, also made of special materials for seawater applications

- Piping of Serviio, instrumentation, process valves

- The interface panel and the interface for local control or management by the DCS

- The sample connection for the sampling, and also made of special materials, for example for applications with sea water, with high-pressure fluids and corrosivity

Hydros realizes solutions with high degree of customization and studied according to the various application requirements

The sludge contained in the wastewater sediment in the lower part of the tank is subsequently sucked or extracted through mechanical systems.

The package can also be provided with systems that can also treat wastewater whose content is formed from fats and oils of different density, using the DAF technology

The advantages of this application are the following:

- Separation efficiency

- CPI system requires about 2/3 of the area committed compared to traditional systems PPI (Parallel Plate Interceptor) with construction costs of the lower civil works.

- Ease of maintenance and use of the system